3D-Printed Orthodontic Aligners

Getting teeth straight and enhancing smile with minimal intervention and pain is the trend of cosmetic dentistry, namely, orthodontics. Orthodontic aligners’ industry has evolved, thanks to the advances of 3D printing technology and CAD/CAM dentistry. Yet, it is difficult for many dental clinics to establish an office-based aligners’ manufacturing as in the case of dental prosthesis. This is mainly because orthodontic aligners need much space, equipment and lab technicians. Nowadays, aligners’ industry requires 3D printers, vacuum/heat press apparatus and finishing tools.

Orthodontists and general dentists experienced in orthodontic aligners’ therapy have long dreamt of easy systems that allow the manufacturing of aligners in the office and within short duration. Now, with the great booming in the 3D printing industry, and with the increasing demand for customized guides, stents and prosthesis, the high-speed 3D printers are now disclosed and the production of functional materials with variable dimensions has become real. This technology will allow dental professionals to directly print the desired aligners and to overcome the hassle of material waste, noise of micro-motors and maintenance of equipment. Dentists by time will rely mainly on this fast technology and will only have to learn about orthodontic software and adjusting 3D printers.

Dental professionals will strongly benefit from such full-digital work cycle and the cost-effective production. It is clearly evident that more dentists and lab technicians now manufacture dentures through digital workflow. 3D printers’ manufacturers are working on achieving more FDA approvals on materials for dentures, clear aligners and even provisional prostheses.

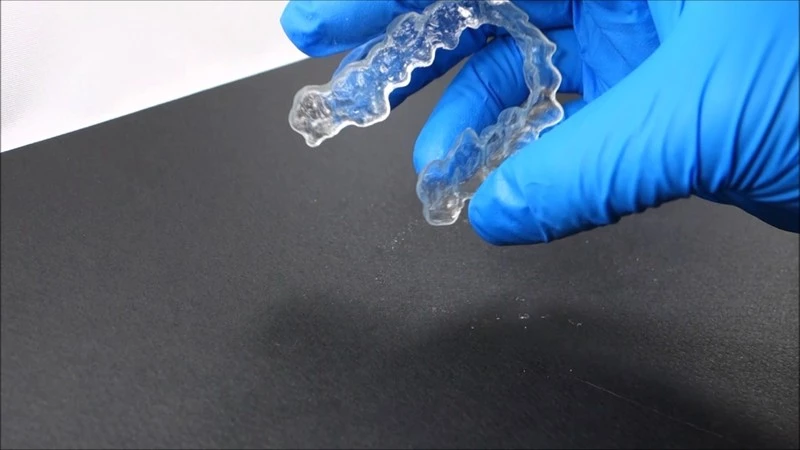

3D-printed orthodontic aligners are unlike those thermoformed on 3D-printed models. They can be directly printed from materials with known biocompatibility, stability, flexibility and strength. Yet, there are some challenges need to be addressed before 3D-printed aligners are the niche of orthodontics over the next years. The first concern arising here is the price and technical complexity of 3D printers; how to make sure of purchasing a 3D printer with high accuracy, repeatability and sophisticated materials to produce quality parts in a consistent fashion over long time. Another concern can be how to adjust the thickness and surface finishing of the aligners and how to produce aligners with smooth margins.