Digital Fabrication of Complete Dentures

CAD/CAM technology is currently used for fabricating wax-up trial dentures or full digitally manufactured complete dentures. Both digital fabrication methods were reproducible, but the accuracy is still inferior to the manual method. The digital workflow for fabricating complete dentures starts with teeth placement and alignment on the software followed by milling the wax trial bases and then modifying the denture in terms of appearance, function and occlusion.

Inaccuracies in digital denture fabrication may result from inaccurate milling, asymmetry between the virtual CAD teeth and the real denture teeth or faulty transferring wax into acrylic resin. STL deviation is another reason for inaccuracy and it is generally found in the area of teeth and the distal part of denture base. The final outcome could be less fitting compared to manual methods.

Controversy exists about the accuracy of digital fabrication methods. Digital scanning and designing provide better visualization of the maxillary and mandibular arches, with possibility to identify anatomic variations. However, when applying scanning powder, the layer thicknesses may count different than their real values and thus affect the results.

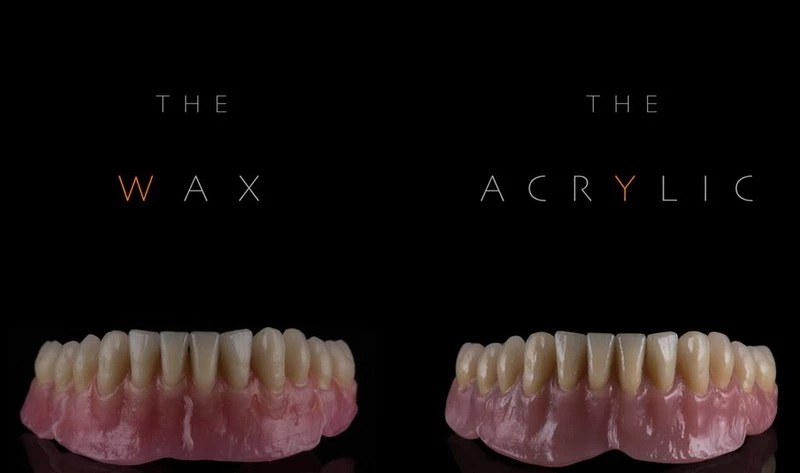

There is a bigger trend now toward full digitally fabricated complete dentures through milling acrylic directly instead of milling wax and then transfer. This is because wax has some thermal instability and molding wax carries high degree of inaccuracy than injection or milling.

Injection procedure itself has lower polymerization shrinkage and, in turn, better accuracy than milling. The major issue here is denture retention which is governed by the amount of shrinkage and the offset provided during designing the denture base which both affect the fluid flow between the denture and the mucosa. Nevertheless, stress/strain forces at the body and margins of the denture base as well as the amount of thermal expansion need to be assessed well to avoid fracture and any changes in occlusion dimensions.

So, dental technicians need to find a fabrication method that merges the advantages of milling with those of injection. Rapid prototyping can be used for digital fabrication of dentures with or without fixative adhesives to bind the teeth to the denture base.

We need now to assess the following shortcomings with the full digital workflow of complete dentures: 1) the effect of the applied spray during the scanning step, 2) the efficacy of 3D printing against injection and milling procedures.